What Is a Hazardous Location?

A hazardous location is an area where there is a risk of an explosion due to the presence of an explosive mixture/atmosphere. For example, common elements that make these areas hazardous include ignitable concentrations of flammable gases, vapors, combustible dust, or ignitable fibers.

These hazardous locations are classified by a system that analyzes and classifies the areas where explosion hazards may exist. This system provides the standard level of protection and precautions that need to be in place before any electrical installations are used in a hazardous area.

What Is Hazardous Area Classification in Oil and Gas?

Hazardous area classification in oil and gas is based on two standards, the British IEC standards, and American ANSI standards. The American system of hazardous area classification according to the National Electrical Code for gases, vapors, and mists are classified as:

- Class I: An area in which an explosion is most likely to occur due to the presence of flammable gas in the air.

- Class II: An area in which an explosion is most likely to occur due to the presence of combustible dust.

- And Class III: An area in which an explosion is most likely to occur due to the presence of easily ignitable fibers.

Furthermore, hazardous areas in all of these classes exist in two different divisions:

- Class I Division: An explosive atmosphere is present during normal operation and is only released due to faulty operation.

- Class II Division: An explosive atmosphere is only present when there is an accident or failure of the ventilation system.

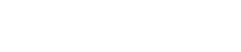

How Does an Explosion Occur?

There are three necessary components, all of which need to be present for an explosion to take place.

These components are:

1. Flammable Substance

A combustible substance that can be easily ignited. When present in a relatively high quantity will produce an explosive mixture (e.g., gas, vapors, mists, and dust).

2. Oxygen

Oxygen acts as an oxidizing agent when combined with a flammable substance. As a result, this produces an explosive atmosphere.

3. Ignition Source

A spark or high heat that causes a flammable substance to ignite/burn.

How to Contain, Segregate, and Prevent an Explosion

Reducing the risk of an explosion calls for more than area classification. For instance, one way to reduce the risk of an explosion is by eliminating one component of the ignition triangle.

There are three ways that this can be done:

Explosion Containment

This method allows the explosion to occur but confines it to a well-defined area using explosion-proof enclosures. Therefore, containing the explosion and preventing the propagation to the surrounding atmosphere.

Segregation

The segregation method attempts to physically separate or isolate the electrical parts or hot surfaces from the explosive mixture using pressurization or encapsulation techniques.

Prevention

This method prevents an explosion from occurring by limiting the energy, electrical and thermal, to safe levels under normal operation and fault conditions. The most efficient and known technique of this method is intrinsic safety. This protection technique stops an explosion from occurring by not allowing the conditions for this to happen.

Catalytic Heaters Help Reduce the Risk of An Explosion

Every hazardous area is different and requires a specific needs assessment to ensure special precautions are implemented to prevent an explosion. One way to keep your equipment running in a hazardous area is by using catalytic heaters. They reduce the risk of an explosion by generating heat without a flame from start to shut down. Hence, helping contain the process and reduce the risk of an explosion propagating.

Keep Your Critical Equipment Working Properly in Hazardous Locations

Our experts are here to help you find the best solution with a range of catalytic heaters designed for use in hazardous environments. Do you want to learn more about how catalytic heaters work? Then check out our complete guide or schedule your product demo today to see it for yourself!